To streamline a business process is to do one simple thing: make it better. It’s about taking a hard look at a workflow and figuring out how to cut out the waste, lower costs, and boost efficiency. This usually involves mapping out how things currently work, pinpointing the exact spots where things get stuck, automating tasks that don't need a human touch, and then keeping an eye on performance to make sure you're always improving.

What Streamlining Your Business Really Means

So, what are we really talking about when we say "streamline business processes"? It’s definitely more than just a corporate buzzword for working faster. It’s a complete shift in how you think—moving away from "this is how we've always done it" and toward relentlessly asking, "how can we do this better?"

It's the difference between a business that feels chaotic and reactive versus one that operates with precision and purpose.

The goal isn't just about speed; it's about achieving strategic wins that create a ripple effect across your entire company. When you get this right, you see real, tangible results:

- Happier Customers: Faster turnaround times, fewer mistakes, and more predictable service create experiences that build serious loyalty.

- More Engaged Employees: Let's be honest—nobody enjoys fighting with clunky, inefficient systems. When you remove that friction, you empower your team to focus on work that actually matters, which boosts both morale and productivity.

- Greater Agility: Lean, optimized processes mean your business can pivot fast. Whether it's a market change, a new opportunity, or an unexpected hiccup, you're ready.

- Reduced Costs: Every unnecessary step, redundant task, or manual workaround is costing you money. Streamlining directly hits your bottom line by cutting out all that operational waste.

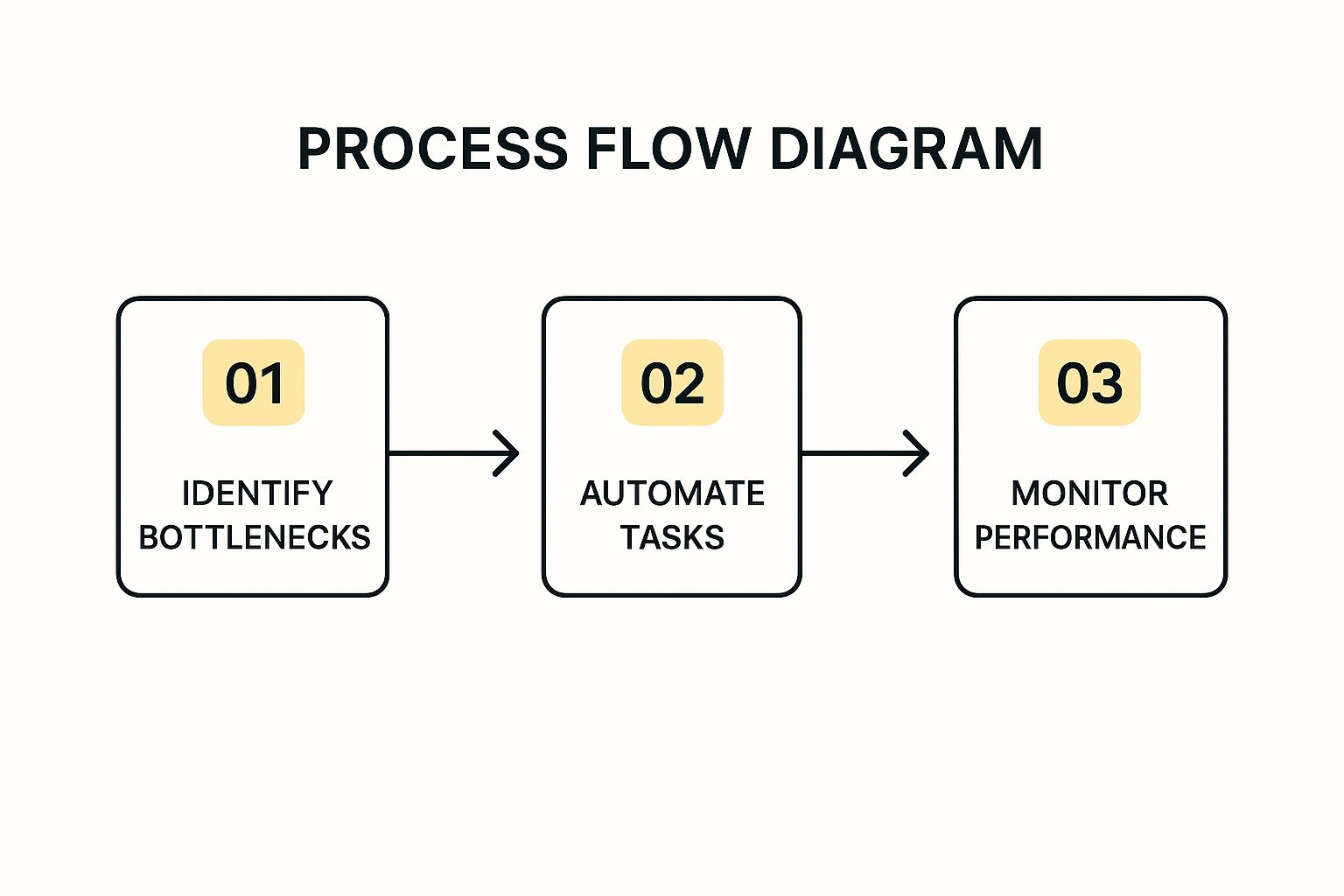

This process flow diagram breaks down the three essential stages: finding the bottlenecks, automating what you can, and then monitoring the results.

This visual makes it clear that streamlining isn’t a one-and-done project. It’s a cycle of continuous improvement.

Core Principles of Streamlining

At its heart, streamlining is built on a few key ideas. The first is a relentless focus on value. This means looking at every single step in a process and asking a simple question: does this actually add value for the customer or the business? If the answer is no, it’s a prime candidate for elimination.

Next up is the ruthless cutting of waste. Waste can show up in a lot of different forms—too many handoffs between teams, long waits for approvals, duplicate data entry, or procedures that are just overly complicated. Finding and killing this waste is central to making any process run better.

Finally, the goal is to create clear, repeatable workflows. Standardization is everything. When everyone follows the same optimized process, you reduce guesswork, minimize errors, and ensure you’re delivering consistent quality every time.

True streamlining isn't about working harder; it's about working smarter. It transforms complex, frustrating tasks into simple, repeatable systems that empower your team and delight your customers.

To give you a clear roadmap for this journey, it helps to break the entire effort down into four distinct stages.

The Four Core Stages of Process Streamlining

Each stage has a specific goal and a set of activities that build on the last one. Following this structure helps you organize your efforts and ensures you're tackling the right problems in the right order for the biggest impact.

| Stage | Objective | Key Activities |

|---|---|---|

| 1. Identify & Map | Gain a complete understanding of the current process and pinpoint inefficiencies. | Interviewing stakeholders, creating detailed process maps (flowcharts), gathering performance data. |

| 2. Analyze & Redesign | Identify the root causes of problems and design a new, improved workflow. | Brainstorming solutions, benchmarking against best practices, creating a "to-be" process map. |

| 3. Implement & Automate | Roll out the new process and use technology to automate manual tasks. | Training employees, configuring automation tools, updating documentation, running pilot tests. |

| 4. Monitor & Improve | Track performance, gather feedback, and make ongoing adjustments for continuous improvement. | Setting up dashboards, defining KPIs, collecting user feedback, conducting regular process reviews. |

Understanding these phases is the first step. It guides you from initial analysis all the way through to full-scale automation and the kind of continuous improvement that keeps your business ahead of the curve.

Mapping Your Workflows to Find Hidden Problems

You can't fix a problem you can't see. It's a simple truth, but it’s the bedrock of any real attempt to make a business run better. Too many companies operate on assumptions about how work should get done, but the reality on the ground is often far messier than what's written in some dusty, outdated manual.

This is where workflow mapping comes in. It’s the first, non-negotiable step to getting a true-to-life picture of your operations. This isn't just an abstract exercise; it's about visualizing every single step, every handover, every decision, and every frustrating delay in a process from its start to its finish. A good map instantly exposes the hidden snags that are otherwise buried in the day-to-day chaos.

The goal here is to create an "as-is" process map—a brutally honest snapshot of your current reality, not the idealized version you think exists. Only then can you actually pinpoint the sources of friction, wasted time, and bloated costs.

Choosing the Right Mapping Technique

Before you gather the team, you need to pick a mapping method that fits the job. You don't always need complex software or a certified expert to get it done. The key is clarity and getting everyone involved. For most businesses, two common approaches work perfectly.

- Simple Flowcharts: This is the easiest place to start. Using basic shapes (ovals for start/end points, rectangles for tasks, diamonds for decisions), you can sketch out a process fast. This method is perfect for straightforward workflows and getting the whole team engaged without a steep learning curve.

- BPMN (Business Process Model and Notation): For more complex operations, BPMN provides a standardized, more detailed language. It uses a specific set of symbols to represent different types of tasks, events, and data flows. It takes a little more learning upfront, but BPMN creates unambiguous maps that are incredibly useful for technical teams and automation projects.

Regardless of which one you choose, the most important part is getting the right people in the room. This isn't a task for a manager to tackle alone in an office.

The real insights always come from the people who live the process every single day. They know the workarounds, the frustrating delays, and the communication breakdowns that never make it into official documentation.

By running collaborative workshops, you get honest answers and create a map that reflects what's actually happening. This shared ownership also builds buy-in for the changes that will inevitably follow.

A Real-World Invoicing Example

Let's look at a common business headache: a messy invoicing process that leads to delayed payments. A small consulting firm thought their process was simple enough. Work gets done, an invoice goes out, and payment comes in. Easy. Yet, their payments were consistently 30-45 days late.

When they actually mapped the workflow, they uncovered the hidden complexities:

- Consultant completes work and emails a summary to the project manager.

- Project manager waits for a weekly meeting to review it with the finance assistant. If someone's on vacation, everything stalls.

- Finance assistant manually creates the invoice in their accounting software, often having to chase the consultant for specific billing codes.

- Invoice is sent to the project manager for a final check, who might not see the email for a day or two.

- Finally, the invoice is emailed to the client’s generic accounts payable inbox.

The map immediately made the bottlenecks painfully obvious. A weekly meeting was causing an initial delay right out of the gate. Manual data entry was creating opportunities for errors. Multiple approval loops were adding days to the process.

What seemed like a "simple" task was actually a tangled web of handovers and wait times. Armed with this visual evidence, the firm could finally start untangling the mess.

Once your workflows are mapped out like this, you can find more proven strategies to improve workflow efficiency, from automation to smarter process design. For more inspiration on how this can be applied, check out these real-world workflow automation examples.

Analyzing Processes to Uncover Smart Improvements

With a detailed workflow map in hand, you’ve moved past assumptions and into the realm of facts. Now, the real detective work begins. A map shows you the path, but the analysis tells you where that path is crumbling. This is where you scrutinize each step to spot the redundancies, bottlenecks, and hidden costs dragging your business down.

It’s tempting to jump straight to solutions, but a disciplined analysis stops you from just treating symptoms. Instead, you can pinpoint the root causes of inefficiency, ensuring any changes you make will actually stick. This is how you turn a simple drawing into a powerful tool for strategic change.

Digging Deeper with Proven Frameworks

To move beyond just staring at a flowchart, you need a structured way to guide your investigation. Two incredibly effective frameworks for this are the "5 Whys" and Value-Stream Mapping. They help you peel back the layers of a problem to find what’s really going on underneath.

The 5 Whys is a simple yet potent technique for getting to the root of an issue. You start with a problem and just keep asking "Why?" until you uncover the foundational issue.

Let’s go back to that late invoicing example. The initial problem is clear: Payments are consistently late.

- Why? Because invoices are being sent out late.

- Why? Because the finance assistant has to chase down billing codes.

- Why? Because consultants aren't including them in their initial work summaries.

- Why? Because the summary template doesn't have a required field for billing codes.

- Why? Because the template was created years ago and never updated to match the new accounting system's requirements.

Suddenly, the root cause isn't a "slow employee"—it's an outdated document. Fixing the template is a far more effective solution than just telling people to work faster.

Separating Value from Waste

Another killer approach is Value-Stream Mapping (VSM). This technique forces you to categorize every single step in your process into one of two buckets: value-adding or non-value-adding.

A value-adding activity is anything the customer would willingly pay for—something that directly contributes to the final product or service. Everything else is waste. Studies show that in many business processes, non-value-adding activities can make up over 60% of the total workflow.

The goal is to maximize the time spent on activities that create value and ruthlessly eliminate or reduce everything else. Waste isn't just about physical materials; it's about wasted time, effort, and potential.

Common forms of operational waste include:

- Waiting: Time spent waiting for approvals, information, or for the previous step to finish.

- Over-processing: Doing more work than necessary, like redundant reviews or excessive reporting.

- Rework: Correcting mistakes or defects, a direct result of a quality breakdown.

- Motion: Unnecessary movement of people, such as walking to a central printer multiple times a day.

- Transportation: Needless movement of files, materials, or information between teams or systems.

By labeling each step on your map as either "value-add" or "waste," you create a clear visual guide showing exactly where to focus your improvement efforts.

Blending Data with Human Insight

Frameworks are great, but they’re most powerful when you combine them with real-world data and feedback. Your analysis needs to be a mix of the qualitative and the quantitative to get the full picture.

Start by gathering the hard data. Look at metrics like:

- Cycle Time: The total time from the start of a process to its end.

- Lead Time: The time from a customer order until delivery.

- Error Rate: The percentage of outputs that have defects or require rework.

- Throughput: The number of items you can process in a given time.

This quantitative data gives you an objective baseline. You can clearly say, "Our invoice approval process currently takes an average of 4.5 days." No arguing with that.

Next, go collect the qualitative stuff. Talk to the people who execute the process every single day. They hold invaluable context that numbers alone just can't provide. Ask open-ended questions like, "What's the most frustrating part of this for you?" or "If you could wave a magic wand and change one thing about this process, what would it be?"

This blend of hard data and human experience is unbeatable. The data tells you what is happening, and your team's feedback tells you why. This combined insight ensures that when you move on to redesigning the process, your solutions are based on solid evidence, targeting the friction points that truly matter.

Using Automation to Drive Peak Performance

After you’ve mapped and analyzed your workflows, this is where the magic happens. Automation is the engine that takes those slick, redesigned processes and puts them on autopilot, running them with a speed and precision you just can't get from manual work. This isn’t about replacing your team; it's about freeing them from the soul-crushing, repetitive tasks that drain their energy.

Once you learn how to streamline business processes, you quickly see that automation is the final piece of the puzzle. It locks in your improvements, slashes human error, and lets your people focus on the stuff that actually matters—like creative problem-solving and strategic thinking.

And it’s not just a nice-to-have. The global automation market is exploding, and firms that get on board see an average 22% reduction in operating costs. This isn't just for the big guys anymore, either. A ton of accessible tools have made it a game-changer for businesses of every size.

Identifying the Best Candidates for Automation

Here's the thing: not every task is a good fit for automation. You've got to be smart about it. The best targets are the jobs that are manual, repetitive, rule-based, and prone to mistakes. These are the tasks your team dreads, and they’re the low-hanging fruit for a killer ROI.

Think about what this looks like in the real world:

- Customer Support: Imagine support tickets automatically getting routed to the right person based on keywords. No more manual sorting.

- Employee Onboarding: A new hire signs their offer, and a sequence kicks off—sending welcome emails, assigning training, and setting up their IT accounts without anyone lifting a finger.

- Finance and Invoicing: Data gets pulled from a purchase order and instantly creates a draft invoice in your accounting software.

See the pattern? These processes are high-volume, follow a predictable path, and don't require deep, complex judgment calls. To really see what's possible, it’s worth exploring some practical business process automation examples to get the ideas flowing.

Understanding Different Levels of Automation

Automation isn't an all-or-nothing deal; it’s a spectrum. You don’t need a massive budget or a team of developers to start making a difference.

Automation should empower your team, not intimidate them. Start with simple tools that solve immediate problems, and you'll build the momentum and confidence needed to tackle more complex challenges later on.

You can start small with basic email rules or by using a tool like Zapier to link your apps together. For the heavier lifting, Robotic Process Automation (RPA) becomes your best friend. RPA uses software "bots" that act like a digital employee, mimicking human actions like logging into apps, copying and pasting data, or filling out forms.

This diagram gives you a great visual of how an RPA bot can work across different systems, just like a person would, but way faster.

The bot interacts with the user interface—the screen you see—so it doesn't need complicated API integrations to get the job done.

Choosing the Right Tools for the Job

The market is flooded with automation software, and picking the right one comes down to your specific needs and technical comfort level. The goal is to find a platform that fits your processes, plays nice with your existing software, and is easy enough for your team to actually use.

Here’s a quick breakdown of the main categories:

| Tool Category | Best For | Example Use Case |

|---|---|---|

| Workflow Automation Platforms | Connecting cloud-based apps for simple "if this, then that" tasks. | A new lead in your CRM automatically triggers a new task in your project management tool. |

| Robotic Process Automation (RPA) | Automating repetitive, high-volume work involving legacy systems or apps without APIs. | A bot logs into an old desktop app, scrapes a report, and enters the data into a modern web system. |

| Business Process Management (BPM) Suites | Managing complex, end-to-end processes that span multiple departments and require human input. | Handling an entire insurance claim, from submission and human review to final payment approval. |

Doing your homework here is key. For a deep dive, check out our guide on the top business process automation tools out there today. It’ll help you match your exact needs with the right solution.

By strategically applying automation, you turn your process map from a plan on paper into a living system that delivers reliable results, every single time. And that frees up your most valuable asset—your people—to innovate, solve big problems, and push your business forward.

Making Your New Processes Stick

Launching a redesigned workflow is a huge accomplishment, but it's really just the starting line. The real test is making sure these new, more efficient processes actually take hold and become the new normal.

Without a solid plan for adoption, even the most brilliant process improvements can wither on the vine as teams slowly drift back to their old, familiar habits. It happens all the time.

Success here isn’t about forcing change down people's throats; it's about leading your team through it. This means clear communication, practical training, and a real system for measuring what's working—and what isn't. This is where you turn a theoretical improvement into a lasting business advantage.

Communicating the Change and Building Confidence

First things first: you have to get everyone on board. That starts with explaining the "why."

Don't just announce a new procedure and expect a standing ovation. Tell the story behind it. Walk your team through the bottlenecks you found and show them exactly how this new process is designed to eliminate the specific frustrations they've been dealing with.

When people understand the purpose, they're far more likely to embrace the change. Frame it as a solution to their problems, not just another top-down mandate from management.

From there, training is everything. But please, skip the boring, text-heavy manuals nobody reads. Effective training is hands-on, interactive, and actually builds confidence.

- Run practical workshops. Get your team to walk through the new process using a real-world scenario. Let them click the buttons and fill out the forms themselves.

- Create quick-reference guides. A simple, one-page checklist or a flowchart is infinitely more useful than a 20-page document.

- Identify and train champions. Find a few enthusiastic team members to act as go-to experts who can provide peer support. It's often less intimidating to ask a coworker for help.

This approach transforms training from a passive event into an active, empowering experience, which is exactly what you need to make the new process stick.

Measuring Success With the Right KPIs

You can't manage what you don't measure. It’s an old saying, but it's true.

To know if your new workflow is actually an improvement, you need to track its performance with clear Key Performance Indicators (KPIs). These metrics give you objective proof that your hard work is paying off.

Don't overcomplicate this. Start with a few simple, powerful KPIs that directly relate to the problems you were trying to solve in the first place.

Your KPIs should tell a clear story. If you aimed to reduce payment delays, track 'Average Days to Payment.' If you wanted to cut down on mistakes, monitor 'Error Rate.' Simple metrics are the most powerful.

Here are a few common process-related KPIs to consider tracking:

- Process Cycle Time: How long does it take to complete the entire workflow from start to finish?

- Task Completion Rate: What percentage of tasks are being completed on time?

- Error or Rework Rate: How often are mistakes happening that require correction?

- Cost Per Process: What’s the total operational cost associated with one run-through of the process?

Tracking these numbers gives you undeniable evidence of your progress. It also helps you understand the direct financial benefits, which is a key component when you measure ROI on your improvement projects.

Creating a Culture of Continuous Improvement

This is the final—and most important—step. You have to establish that streamlining is a cycle, not a one-and-done project. The most efficient companies I've seen are the ones that are always looking for small ways to get better.

This requires creating a system for ongoing feedback and iteration.

Set up a simple feedback loop where your team can easily suggest tweaks. This could be a dedicated Slack channel, a monthly review meeting, or even a simple suggestion box. The tool doesn't matter as much as the habit.

When an employee flags an issue or has a smart idea, acknowledge it. And if it makes sense, act on it.

This does two powerful things. First, it ensures your processes continue to evolve and don't get stale. Second, it gives your team a sense of ownership, transforming them from passive participants into active partners in the company’s success. That cultural shift is the real goal here—building an organization that's resilient, agile, and always improving.

Common Questions About Streamlining Processes

Jumping into process improvement usually brings up a flood of questions. It's natural to wonder where to start, how to handle the human side of change, and what will actually deliver the biggest bang for your buck. Let's tackle some of the most common hurdles people hit when they decide to streamline their business.

Getting these answers straight can be the difference between a project that builds momentum and one that stalls out before it even gets going.

Where Is the Best Place to Start?

The sheer number of processes in any business can feel overwhelming, making it tough to pick a starting point. The key is to look for the intersection of high impact and high friction.

Don't start with a minor, obscure workflow. Instead, target a process that is both critical to your business and notoriously frustrating for your team or your customers.

A few prime candidates often include:

- Customer Onboarding: A clunky onboarding experience poisons the well from day one, directly impacting customer satisfaction and retention.

- Invoicing and Accounts Payable: Delays and errors here hit your cash flow, a metric nobody can ignore.

- Employee Onboarding: A chaotic first week for a new hire sets a poor impression and can seriously slow down their time-to-productivity.

The best starting point is almost always a process where the pain is obvious. When everyone on the team agrees that "the way we handle X is a total mess," you already have the built-in motivation needed to drive change.

By picking a process that visibly hurts the business, you make it easier to show the value of your work right away. This creates a powerful success story that builds support for whatever you tackle next.

How Do I Get My Team on Board?

Resistance to change is one of the biggest roadblocks to successful process improvement. You can design the most efficient workflow in the world, but if your team doesn't adopt it, it's completely worthless. Getting buy-in isn't about issuing commands from on high; it's about inclusion and communication.

Start by involving the team from the very beginning. The people who execute a process every day are your single greatest source of information about what’s actually broken. Ask them for their insights during the mapping and analysis phases. This approach makes them feel heard and valued, transforming them from passive recipients of change into active partners in building the solution.

Frame the changes around benefits that matter to them. Instead of saying, "This will increase efficiency by 15%," try something like, "This new process will eliminate that manual data entry you all hate doing every Friday afternoon." When employees see how streamlining makes their own jobs less frustrating, resistance quickly turns into enthusiasm.

Which Processes Offer the Biggest Payoff?

While starting with a high-pain process is a great strategy, you also want to think about where you'll get the most significant return on your effort. The biggest payoffs usually come from automating tasks that are high-volume, repetitive, and rule-based.

Think about the work that happens over and over, the same way, every single day. This is the low-hanging fruit for automation.

Here are a few areas known for delivering a quick and substantial ROI:

| Process Area | Why It's a Big Win | Example Improvement |

|---|---|---|

| Data Entry & Transfer | Extremely time-consuming and a magnet for human error. | Automatically moving customer data from a web form straight into your CRM. |

| Report Generation | Often involves manually pulling data from multiple, disconnected sources. | Scheduling a bot to compile and email a sales report every morning. |

| Approval Workflows | Manual approvals create significant delays and bottlenecks. | Setting up an automated system that routes expense reports to the right manager. |

Focusing on these types of processes delivers immediate time savings and a noticeable drop in errors. These quick wins not only improve your bottom line but also free up your team’s time for more strategic, high-value work—which is the ultimate goal of learning how to streamline business processes effectively.

At Up North Media, we specialize in creating custom AI solutions and web applications that automate your most challenging workflows. If you're ready to turn operational friction into a competitive advantage, we can help. Schedule your free consultation today!